Lunar Module Engineering: The Eagle’s Landing System: A Precision Feat

The Lunar Module’s landing system was a marvel of engineering that made the Apollo 11 mission possible. This intricate system allowed Neil Armstrong and Buzz Aldrin to touch down on the Moon’s surface with incredible accuracy. Let’s dive into the details of this remarkable feat of technology.

The Birth of the Lunar Module

The Apollo Lunar Module, originally called the Lunar Excursion Module (LEM), was the brainchild of Grumman aerospace engineer Thomas J. Kelly[1]. It was designed to ferry two astronauts from lunar orbit to the Moon’s surface and back. The LM’s development was a response to NASA’s choice of the Lunar Orbit Rendezvous (LOR) mission profile[2].

From Concept to Reality

The initial LEM design looked like a miniature version of the Apollo command and service module – a cone-shaped cabin on top of a cylindrical propulsion section with folding legs[1]. However, this concept evolved significantly:

1. The second design featured a helicopter-like cockpit with large curved windows for better visibility during landing[1].

2. The landing gear went through several iterations, starting with three legs (too unstable), then five (too heavy), before settling on four legs as the optimal compromise[1].

The Eagle’s Landing System: A Closer Look

The Lunar Module’s landing system was a complex network of components working in harmony. Let’s break it down:

Descent Engine

The heart of the landing system was the Descent Propulsion System (DPS)[4]. This powerful engine could be throttled between 10% and 60% of its maximum thrust, giving the astronauts precise control during the landing sequence[4].

Reaction Control System (RCS)

The RCS consisted of four pods, each containing four small thrusters[4]. These provided attitude control, allowing the LM to rotate and adjust its orientation during descent.

Landing Radar

The landing radar was crucial for providing accurate altitude and velocity data as the LM approached the lunar surface[7].

Contact Probes

Three 67.2-inch (1.71 m) probes extended from the LM’s footpads[1]. When any of these probes touched the lunar surface, it activated a contact indicator light, signaling the commander to shut off the descent engine[1].

The Landing Sequence: A Precision Dance

The landing sequence was a carefully choreographed series of maneuvers that began about 260 nautical miles (480 km) from the landing site[1]. Here’s how it unfolded:

1. **Descent Orbit Insertion**: A 30-second burn dropped the LM’s orbit to within 50,000 feet (15 km) of the lunar surface[1].

2. **Powered Descent**: The main phase of landing began at an altitude of about 26,000 feet[6]. The descent engine fired continuously for over 12 minutes, providing braking thrust[6].

3. **High Gate**: At about 7,500 feet (2.2 km), the LM reached the “High Gate” point[4]. This marked the beginning of the approach phase, where the astronauts could see the landing site[4].

4. **Final Approach**: Starting at about 2,000 feet (0.61 km) altitude, the commander took manual control[1]. This phase allowed for last-minute adjustments to avoid obstacles like boulder fields[4].

5. **Touchdown**: The contact probes signaled surface contact, and the commander shut off the descent engine, allowing the LM to settle onto the Moon[1].

How Hard Was It to Fly, Operate, and Land the Apollo Lunar Module?

Engineering Challenges and Solutions

Creating a spacecraft capable of landing on the Moon presented numerous challenges. Here are some of the key issues and how engineers solved them:

Weight Reduction

The biggest challenge was keeping the LM as light as possible[5]. Engineers tested and re-tested every component to ensure reliability while minimizing weight[5].

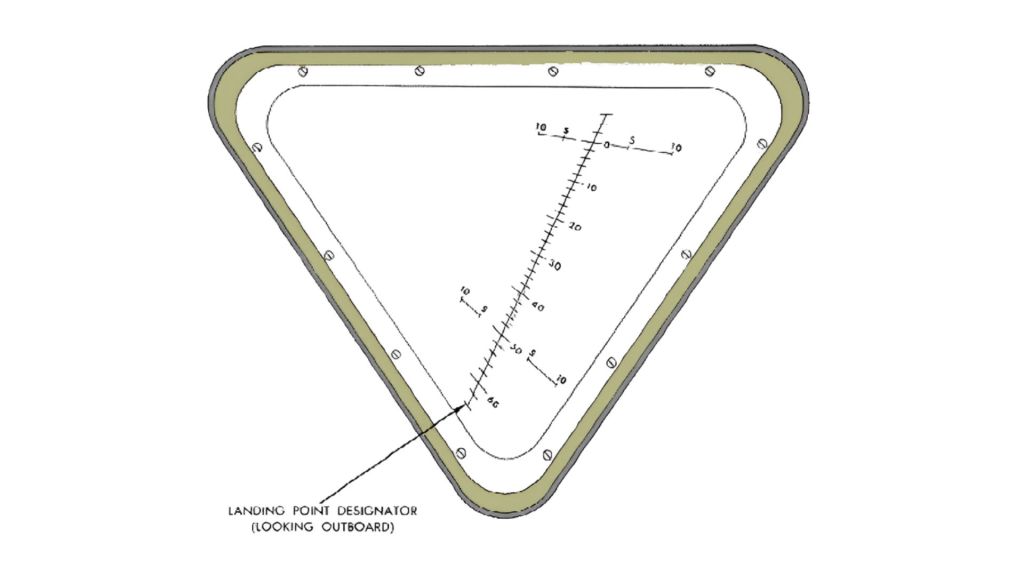

Visibility

The LM’s windows were crucial for manual control during landing[3]. The final design featured two triangular windows canted downward and inward, providing an excellent field of view for the standing astronauts[3].

Structural Integrity

The LM had to withstand the stresses of launch, space travel, and lunar landing. Grumman used a structural test model to verify the LM’s design under various load conditions[7].

Lunar Module Engineering: Designing for a Harsh Environment.

Precision Control

The landing system needed to be incredibly precise. The Apollo Guidance Computer (AGC) handled most of the descent, with the commander taking manual control only for the final approach[4].

The Eagle’s Historic Landing

On July 20, 1969, at 102 hours and 45 minutes into the Apollo 11 mission, the Eagle landed in the Sea of Tranquility[6]. The landing occurred about four miles downrange from the predicted touchdown point and about 90 seconds earlier than scheduled[6].

Armstrong’s skilled piloting was crucial in the final moments. He had to fly the LM over a boulder field to find a suitable landing area[4]. The powered descent lasted only 40 seconds longer than preflight planning, a testament to the precision of the landing system[6].

Detailed Technical Specifications of the Lunar Module Landing System

The engineering marvel of the Lunar Module’s landing system was defined by its precise technical specifications that pushed the boundaries of 1960s aerospace technology.

Descent Engine Specifications

– Thrust: 10,125 pounds (45.04 kN) at sea level

– Specific Impulse: 311 seconds

– Propellant: Aerozine 50 (fuel) and Nitrogen Tetroxide (oxidizer)

– Burn Time: Approximately 756 seconds (12.6 minutes)

– Throttle Range: 10-60% of maximum thrust

Structural Weight Breakdown

– Total Lunar Module Weight: 33,500 pounds (15,200 kg)

– Descent Stage Weight: 22,600 pounds (10,250 kg)

– Ascent Stage Weight: 10,900 pounds (4,950 kg)

Landing Gear Engineering

– Number of Legs: 4

– Leg Length: Approximately 9.5 feet (2.9 meters) when extended

– Shock Absorption: Telescoping struts with honeycomb aluminum crushable bumpers

– Footpad Diameter: 36 inches (91 cm)

– Footpad Design: Circular plate with shock-absorbing capabilities

Guidance and Control Systems

– Computer: Apollo Guidance Computer (AGC)

– Processing Speed: 40 kilohertz

– Memory: 4 kilobytes of RAM, 72 kilobytes of ROM

– Precision Landing Accuracy: Within 220 yards (200 meters) of the target site

Propulsion Control Specifications

– Reaction Control System (RCS) Thrusters: 16 total

– Thruster Thrust: 100 pounds (445 N) each

– Attitude Control Precision: ±0.5 degrees

Unique Engineering Challenges

1. Weight reduction was critical – every pound mattered

2. Designing for unknown lunar surface conditions

3. Creating a landing system that could operate in a vacuum

4. Ensuring reliability with minimal computational power

The technical specifications reveal the extraordinary engineering achievement of creating a spacecraft capable of precision landing on another celestial body with 1960s technology. Each component was meticulously designed, tested, and refined to create a system that would successfully land humans on the Moon.

Legacy and Impact

The success of the Lunar Module’s landing system paved the way for five more Apollo missions to land on the Moon[7]. Each mission is built upon the knowledge gained from previous landings, allowing for more precise targeting and systematic lunar exploration[8].

The LM’s design and engineering principles continue to influence spacecraft design today. In 2002, the American Society of Mechanical Engineers designated the Lunar Module as a historic mechanical engineering landmark, recognizing its groundbreaking achievements[5].

Conclusion

The Lunar Module’s landing system was a triumph of engineering that turned science fiction into reality. It combined cutting-edge technology with human skill to achieve one of the greatest feats in human history. As we look to future lunar missions and beyond, the lessons learned from the Eagle’s landing continue to guide and inspire engineers and space enthusiasts alike.

The precision, innovation, and sheer audacity of the Lunar Module’s landing system serve as a reminder of what we can achieve when we push the boundaries of technology and human ingenuity. It’s a legacy that continues to inspire and challenge us to reach for the stars.

Citations:

[1] https://en.wikipedia.org/wiki/Apollo_Lunar_Module

[2] https://en.wikipedia.org/wiki/Apollo_program

[4] https://blog.adacore.com/make-with-ada-the-eagle-has-landed

[5] https://www.asme.org/topics-resources/content/engineers-remember-the-making-of-the-lunar-module

[6] https://www.nasa.gov/history/apollo-11-mission-overview/

[7] https://fi.edu/en/apollo-lunar-module-structural-test-model

[9] https://ethw.org/First-Hand:Signal_Processing_for_the_Lunar_Module

[10] https://airandspace.si.edu/explore/stories/apollo-11-launch-vehicle-and-spacecraft

How Did Apollo Astronauts Sleep in Low Moon Gravity? Lunar Module Slumber Revealed.