Apollo 11 Windows: A Closer Look at the Engineering Marvels That Took Us to the Moon

“That’s one small step for a man, one giant leap for mankind.” These iconic words, spoken by Neil Armstrong, resonate with the awe and wonder of the Apollo 11 mission. But beyond the giant leaps and lunar landscapes, countless unsung heroes of engineering made this historic event possible. Among them are the windows of the Apollo 11 spacecraft, which served as our eyes on the moon and a shield against the harsh realities of space. These were not just ordinary panes of glass; they were meticulously designed, multi-layered marvels of engineering.

The Need for Windows in Space: More Than Just a View

Why did the Apollo 11 spacecraft need windows at all? Couldn’t the astronauts just rely on instruments? The answer is that windows were crucial for several reasons:

- Observation: The most obvious need was for observation. Astronauts needed to see their surroundings, both in orbit and on the lunar surface. This visual information was crucial for navigation, landing site selection, and overall situational awareness.

- Navigation: During the lunar descent, the astronauts used markings on the Lunar Module windows to calculate their altitude, a vital task given the limitations of the radar altimeter at higher altitudes[1][9]. By timing how long it took lunar landmarks to pass over these markings, they could calculate their angular rate and altitude.

- Safety: Windows provided a visual reference for astronauts to monitor their surroundings, making it easier to avoid hazards and react to unexpected situations.

- Scientific Observation: While not the primary purpose, the windows did afford the astronauts opportunities to make scientific observations of the lunar surface and, during the mission, Earth, which were crucial to understanding the lunar environment.

Design and Materials: A Multi-Layered Approach

The Apollo 11 windows weren’t simple panes of glass like those in our homes. They were complex, multi-layered systems designed to withstand the extreme conditions of space, including dramatic temperature swings and radiation bombardment.

Command Module (Columbia) Windows:

- The Command Module (CM) had five double-paned windows: one in the hatch, two side windows, and two rendezvous windows[10].

- Each window had an outer heat-shield window and an inner-pressure vessel window.

- The inner windows were made of two layers of tempered aluminosilicate glass with a dry inert gas (Nitrogen) in between to create an insulation layer and redundancy. Tempered glass was chosen for its strength.

- The outer windows were made of fused silica, known for its high melting point (3110°F or 1710°C) and resistance to heat. They were designed to protect against the extreme temperatures generated during re-entry.

- An electrically conductive coating was also applied to the outer pane to prevent fogging.

- The windows were mounted to minimize installation stress, ensuring they would primarily handle pressure from the spacecraft.

The Windows that Guided Apollo 11: A Corning Masterpiece

When it comes to the Apollo 11 mission, Corning Incorporated was more than just a supplier; they were a crucial partner in its success. Corning’s expertise in creating specialized glass products made them the go-to manufacturer for the windows of every manned U.S. space flight, from the early days of the Mercury program through the Space Shuttle era. The Apollo 11 lunar landing was no exception, and their work ensured that the astronauts had a clear view of the mission, even in the extreme environment of space.

Space is a harsh mistress, and the windows of Apollo 11 had to be built to withstand the most extreme conditions imaginable. Temperatures could reach a scorching 3,000 degrees Fahrenheit on the sun-facing side, while the opposite side would be in the absolute vacuum of space. To deal with these challenges, Corning developed robust, multi-layered windows that were designed for maximum durability and safety.

The lunar module windows were not just simple panes of glass; they were triple-paned, precision-engineered masterpieces. Each layer was specifically designed for a particular purpose. Here’s how it all stacked up:

- Outer Pane: The outermost layer was made of a synthetic, incredibly pure form of fused silica. This material was chosen because of its ability to withstand intense thermal stress without darkening or losing its clarity under the harsh conditions of space. The higher the purity, the better the performance!

- Middle Pane: A redundant layer was positioned as a backup for additional security. It was there for an “in case of emergency” scenario, adding an extra layer of protection to keep the astronauts safe.

- Inner Pane: The innermost layer was made of aluminosilicate glass, serving as a pressure pane. This layer was tasked with the critical job of maintaining the cabin’s internal pressure against the vacuum of space, ensuring a comfortable environment for the astronauts.

But Corning’s contributions didn’t stop with the windows. They also supplied a plethora of vital components for two Apollo lunar landings, including everything from the fiber optics in the television cameras, to the computer memories and a variety of other electrical components like resistors, capacitors, and integrated circuits.

They also provided the radio antenna covers. These contributions only underscore Corning’s integral and wide-reaching role in the story of space exploration, solidifying its place in space exploration history.

Lunar Module (Eagle) Windows:

- The Lunar Module (LM) had two forward, triangular-shaped windows. These windows were a crucial design choice to save weight.

- Each window had two panes,[1][2][6][11][12] an outer pane made of Vycor glass with a multilayer blue-red thermal coating (to protect from radiation and heat) and an antireflective metallic oxide coating.[8]

- The inner pane was made of chemically tempered Chemcor glass, known for its high strength.

- The inner pane was sealed with a Raco seal and had a defogging coating on the outer surface and an anti-reflective coating on the inner surface.[6]

- Both panes were bolted to the window frame using retainers, and the cavity between the two panes was vented to space.

- The windows were also electrically heated to prevent fogging.

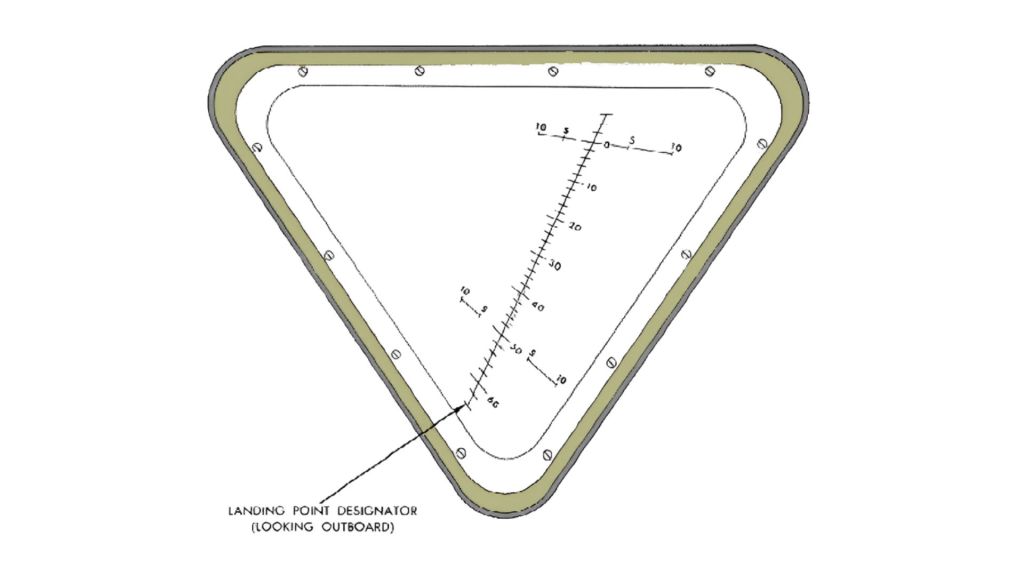

- Notably, the LM windows were marked with a landing point designator, which helped the astronauts target the landing zone.

Manufacturing and Testing: Precision and Rigor

Creating these spacecraft windows was no easy feat. They had to be manufactured with extreme precision and tested rigorously to ensure their reliability.

- Precision Manufacturing: The glass panes were cut and shaped to exact specifications. The multi-layered approach required each piece to fit perfectly into the window assembly.

- Tempering: The glass was tempered to increase its strength and resistance to breaking. This was crucial as the windows had to withstand significant pressure changes and other stresses. Chemically tempered glass was used in the Lunar Module.

- Rigorous Testing: Before being installed in the spacecraft, the windows were subjected to a variety of tests. These tests included pressure tests, thermal tests, and impact tests to simulate the conditions they would encounter during the mission. They were also tested for their optical properties.[11]

The Lunar Module Window: A Portal to the Moon

The Lunar Module’s triangular windows were essential during the moon landing. These windows offered a panoramic view, enabling the astronauts to observe the lunar landscape.

- Landing Assistance: The markings on the windows allowed Neil Armstrong to calculate the distance remaining and adjust the lunar module’s trajectory, playing a vital role in the safe landing of the Eagle.

- Navigational Aid: The windows gave astronauts a visual reference to help orient themselves and navigate the terrain.

- Overcoming Challenges: When the lunar module overshot its initial landing site, the windows allowed Armstrong to assess the new landing zone. He was able to use his view of the landscape to manually pilot the craft and find a safe area to land, a testament to the importance of the windows during the mission.

The Command Module Window: A Link to Home

While the Lunar Module’s windows provided a view of the lunar surface, the Command Module windows gave the astronauts a connection to Earth.

- Re-entry Protection: The outer fused silica panes of the Command Module windows were vital for protecting the astronauts from the extreme heat generated during re-entry into Earth’s atmosphere.

- Observation: The Command Module windows offered the astronauts a view of Earth as they made their journey back home.

- Hatch Window: The hatch window, in particular, was used to view the Earthrise, an iconic moment of the mission.

Challenges and Solutions: Overcoming the Obstacles

The Apollo 11 mission was not without its challenges, including those related to windows.

- Contamination: There were concerns about window contamination from waste-water-system expulsions and crystallizing during cold periods.

- Structural Concerns: Early on, there was a misunderstanding of the structural characteristics of glass, which led to inadequate design verification. Fracture mechanics analysis was used to rectify this issue.

Legacy and Inspiration: The Impact of Apollo 11 Windows

The design of the Apollo 11 windows had a lasting impact on subsequent spacecraft design and how we approach space travel.

- Materials Science: The use of fused silica, tempered glass, and other advanced materials pushed the boundaries of materials science, resulting in the development of stronger and more heat-resistant windows.

- Engineering Principles: The multi-layered approach and precision manufacturing techniques developed for Apollo 11 windows have become standard practice in spacecraft design.

- Inspiration for Future Missions: The success of the Apollo 11 windows paved the way for future missions by demonstrating the effectiveness of carefully designed, technologically advanced windows.

- Corning’s Contribution: It is noteworthy that Corning played a significant role in the Apollo program, supplying heat-resistant windows, including the fused silica used in the Apollo 11 Lunar Module windows. They continue to be a major supplier of space-grade glass.

- Symbolism: The Apollo 11 windows are more than just pieces of glass. They are symbols of human ingenuity, collaboration, and the insatiable desire to explore the universe.

Conclusion

The windows of the Apollo 11 spacecraft were essential elements that played a critical role in the mission’s success. They allowed astronauts to see the moon, navigate during the descent, observe scientific phenomena, and safely return home. These meticulously engineered marvels are a testament to human innovation and a reminder of what we can achieve when we push the boundaries of what’s possible. The next time you look at a photo of the Apollo 11 astronauts on the moon, remember the crucial role those windows played in allowing us to witness this extraordinary feat of exploration. They weren’t just windows; they were our eyes on the moon.

Sources

- blogspot.com

- cmog.org

- concordaerospace.com

- pinterest.com

- nasa.gov

- usra.edu

- si.edu

- core.ac.uk

- stackexchange.com

- sciencemuseum.org.uk

- space.com

- bbc.co.uk

What is the Grid Pattern in the Lunar Module’s Window? Understanding the Landing Point Designator (LPD)